3D Aviation Parts

From precise low-scale prototypes to aircraft parts and components, 3D printing technology has improved and facilitated production for several companies in a variety of industries, such as automotive, robotics, education, and mainly the Aerospace industry. Its wide range of benefits such as reducing costs, weight, and lower production time; it's what caught the attention of the aerospace legacy companies. Aircraft manufacturers are always on the lookout for innovative technology to make aircrafts lighter and efficient, improving payload while not impacting their aerodynamics.

Development within the industry

In June 2014, for the first time, Airbus installed a 3D printed metal-titanium bracket and it has been in the skies servicing commercial jetliners ever since. The company’s progress with 3D printing, also known as additive manufacturing has improved significantly rebooting futuristic ideas making it possible to“print” an entire pilotless aircraft, as part of a project called THOR.

THOR

Boeing has been implementing research and development in 3D printing since 1997. Currently, it has more than 70,000 aircraft parts installed in commercial and military aircraft.

Last year 2020, Honeywell received its first FAA certification for a flight-critical engine component, #⅘ bearing housing for the ATF3-6 Turbofan engine, paving the way for more of these aerospace parts to be certified since they face heavy scrutiny and high standards for qualification prior to installation.

ATF3-6 Turbofan

NASA has been deeply involved with this technology to be able to perform long-term missions. With astronauts discovering more about outer space reaching greater distances, the more resources they use taking a toll on the spacecraft which is where this technology comes in. In 2014, the International Space Station received its first 3d printer. After dozens of tests, they were able to successfully print tools and equipment for the astronauts, increasing the reliability and safety of space missions. They were also able to develop a recycling system to reduce the supply of material for printing and make use of disposable material, reducing the spacecraft’s payload. NASA continues to expand its research trying to make 3D-printed food! These advances can make long-term space missions a reality in the nearby future.

3D-Printed Pizza

Benefits and composition of the parts

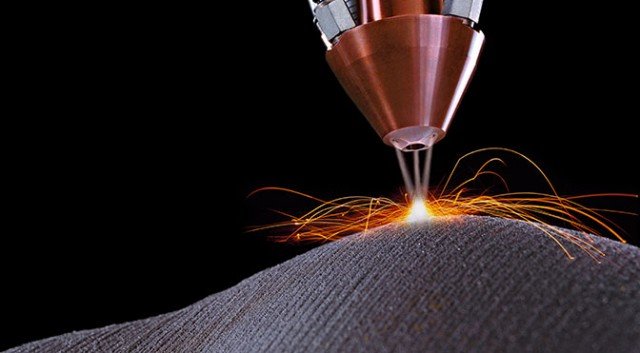

Additive manufacturing or 3D Printed Parts are initially mostly made with carbon fiber mixed with multiple metals, under the fused deposition modeling (FDM) method; which prints layer by layer of the object making it symmetrical and exact.

Carbon fiber allows the material to be much more resistant allowing less and less metal to be used in the production of parts. Tests made by Airbus revealed that the metal used was between 30% to 50% less, compared to a traditional airplane that approximately uses more than 70% in only metal parts. This technology opens the door for airplanes being 3 times lighter. Its construction uses fewer tools and takes less time for delivery. The physical accuracy of the printed parts is what makes this experiment successful; without the correct symmetry of them, safety is at risk; No minimum detail can be missed. The tests carried out showed that airplanes can be 20% faster and more aerodynamic, which is a great advantage in delivery dates and much more advances in the aerospace industry.

Thanks to the weight being reduced because of the materials used, it leads to less fuel consumption which means less CO2 emissions to the atmosphere.

Apart from being an innovative invention, 3D printing puts into context the needs of companies with respect to aircraft parts’ production in addition to their safety and availability. Making it easier and faster to replace parts that have suffered wear and tear, and supplying them with completely new and airworthy parts.

The Forecast

The advancement of this technology continues to move at a faster pace, 3D-printed aircraft parts are already fulfilling their main material with metals. It is predicted that once this technology is implemented as standard production procedure, planes will be delivered faster and with less ground time while in maintenance.

3D Printing still has a long way to go to reach its full potential for practical usage. Printed aircraft parts procurement is our daily duty to keep your aircraft flying, and Login Aviation is here to supply you with anything you need. We work with multiple manufacturers, including Honeywell, to make any aircraft component available and accessible for your aircraft.